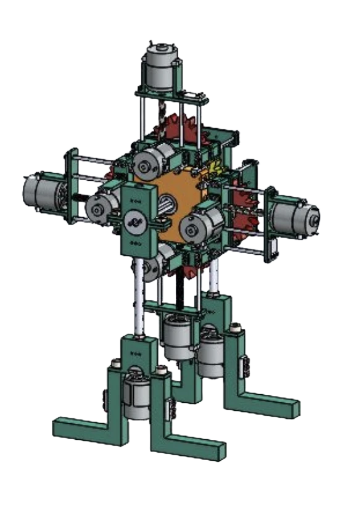

Project: Design automated transmission mechanism.

To design this mobile mechanism for adjusting planetary gears, several key aspects had to be taken into account. First, a detailed analysis of the geometry and dimensions of the planetary gears, as well as the desired transmission ratio, was carried out. From this information, the optimal number of teeth and pitch angle for each gear were determined.

In addition, appropriate materials for manufacturing the gears must be considered, taking into account the required strength and durability. Subsequently, a mobile mechanism that allows the necessary gear adjustments to be made, either through a screw system or a lever system, had to be considered. This mechanism must be precise and easy to operate to ensure optimal adjustment of the planetary gears.

In short, a thorough analysis and careful planning were required to ensure efficient operation. Keep in mind that the proposal requirements emphasized functionality, innovation, and versatility. The design of this proposal was developed using Dassault Systemes Solidworks software, and manufacturing planning was performed using Fagor simulators. Material and shop floor estimates, monitoring and evaluation criteria, project progress indicators, and risk management criteria were provided.